Magnolia Bronze: Cast in Steel

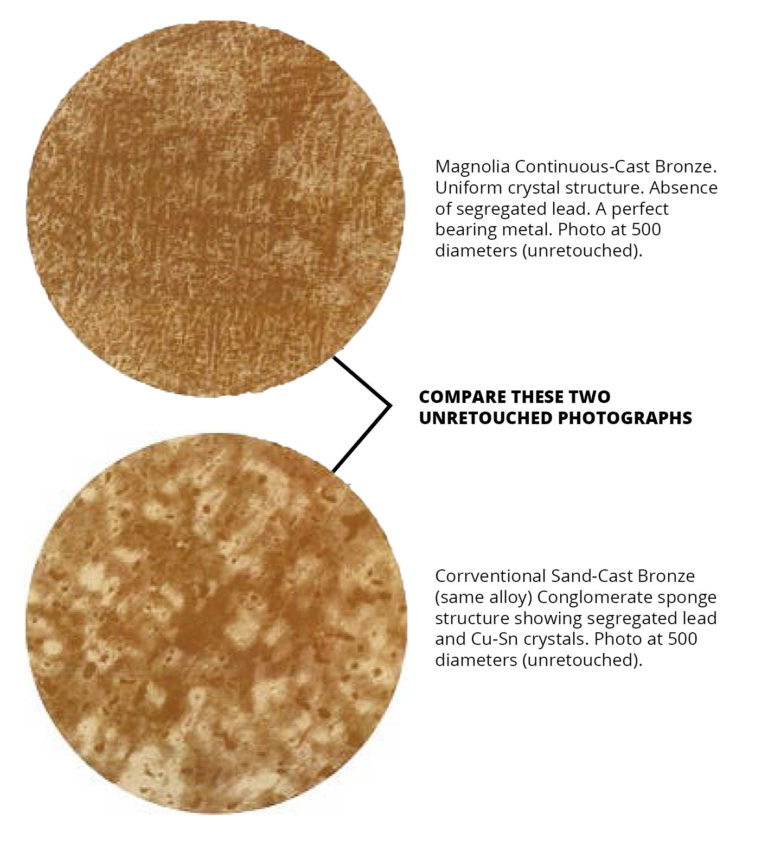

Bronze is really a “mixture,” not an alloy; the faster it cools, the more homogenous the mix. The continuous cast process permits the metal to chill quickly, producing an even or isotropic crystal structure. Blowholes and inclusions are eliminated; the customer is assured of a uniformity and reliability unobtainable in sand casting.

SAVE WITH MAGNOLIA CONTINUOUS CAST BRONZE!

1. Save ON MACHINING!

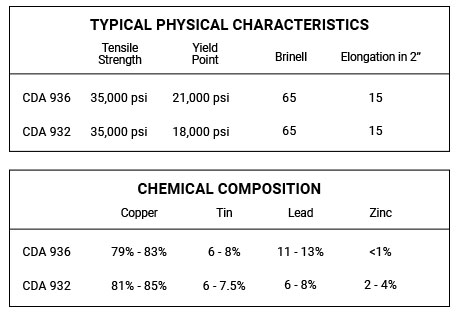

Magnolia Continuous-Cast Bronze can be finish machined at high speeds and feeds. A skin cut will finish machine Magnolia Continuous-Cast Bronze to nominal size. It is never necessary to finish machine a second time since Magnolia CDA 936 (Modified SAE 64) holds the finished dimensions to which it is machined. With it’s lower zinc content, CDA 936 machines 13% more freely than CDA 932 (SAE 660). This means longer tool life and less machine time in your shops.

2. Save WITH LESS WEIGHT

Magnolia Continuous-Cast Bronze finish machines to the size you order. It is never necessary to purchase “oversize” castings if you buy Magnolia Continuous-Cast Bronze. Purchase the exact diameters and lengths to which you want to finish machine. Let Magnolia cut your blanks, eliminating wasteful scrap ends.

3. Save BY RECYCLING

Magnolia will buy back scrap if kept separate and dry. Reduce your total cost by returning solids and clean turnings directly to the mill.

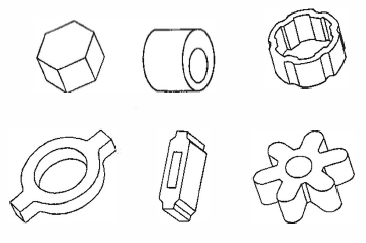

4. Save with special shapes

Magnolia will buy back scrap if kept separate and dry. Reduce your total cost by returning solids and clean turnings directly to the mill.

Resolve your lead concerns the easy way with our B-1 Bronze. It’s the best alternative.

- Superior performance characteristics required in bearings ”

- Lower net cost than generic lead-free bronzes

- Addresses environmental and workplace concerns

MAGNOLIA CAN:

FINISH MACHINE TO YOUR SPECIFICATIONS SERVE ALL YOUR FINISHED PART NEEDS

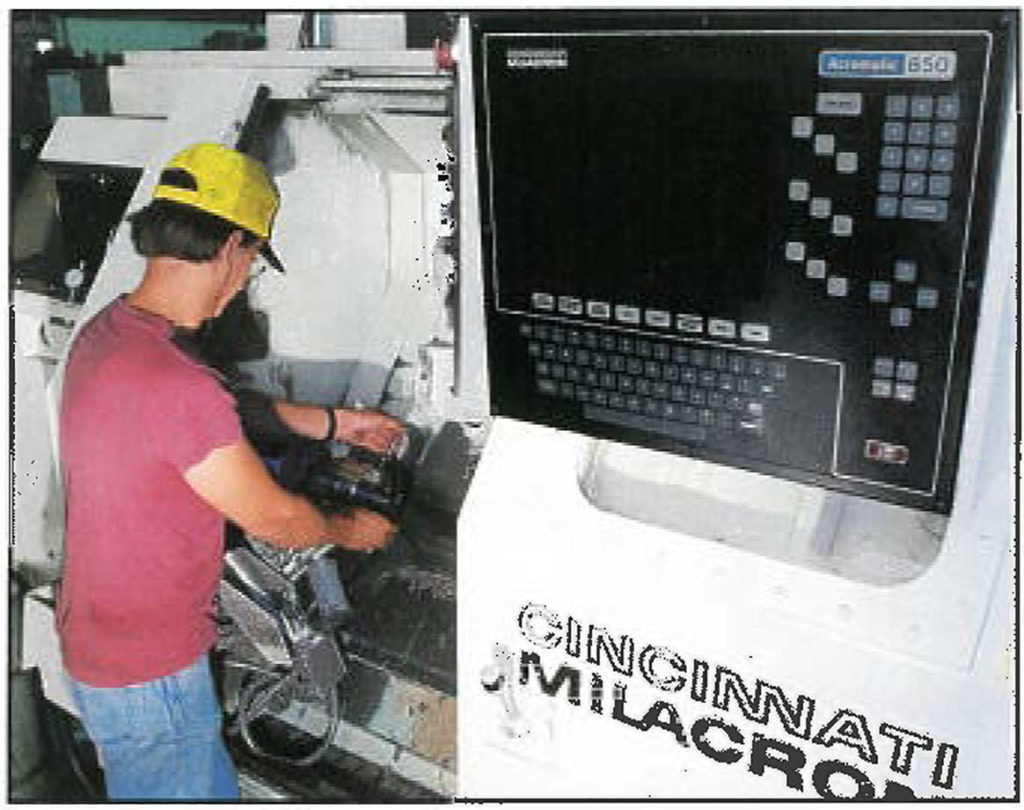

COMPUTER NUMERICALLY CONTROLLED LATHES

• 10 to 1,000 pieces, up to 10″ O.D.• 10 to 1,000 pieces, up to 10″ O.D.

• Capable of intricate detailing and exacting tolerances.

FINISHED PARTS OR BLANKS UPTO 34″ O.D.

Full Detailing

- Graphiting

- Milling

- Grooving

- Drilling

- Chamfering

- Split & Sweats

- Lugs

- Precision Guaranteed

- QC Certification

Magnolia Guarantees No Rejects

Magnolia Bronzes are guaranteed to be free from all defects. In Magnolia Bronze there are no blow-holes, no sand spots, no segregated elements, no flaws… no under-surface faults of any kind to cause rejection.

In accordance with industry practice, guarantee is limited to free placement of material returned. But why just “hope” to get a good casting? Magnolia’s quality control procedure has resulted in returns of less than 1/2 of 1% of all bronze shipped over the last 10 years. This standard of excellence combined with our special alloy and our unique casting process assures you of the best possible value in bearing bronze.