STEEL-CAST MAGNOLIA BRONZE BEARINGS

Whatever your bronze needs, we stand ready to respond. Maintaining a large inventory and wide range of sizes in stock enables us to act immediately in a critical delivery situation. With the elimination of patterns, core boxes and costly rejects, your savings on replacement parts are considerable. Combine that with our computerized costing system, upgraded machining equipment and our own foundry, and see why we provide among the most competitive prices in the industry.

Magnolia casts and stocks CDA 937 (Cert 64), #120 High lead Bronze (20% lead) similar to n SAE 67 Alloy, AA Hard or CDA 903 and SAE 63. In addition to these standard alloys, we arecapable of casting most tin bronzes and leaded tin bronzes on a special order basis.

- All bushings are centrifugally cast in slowly rotating steel molds. No sand is used in manufacture. This entirely eliminates patterns and core boxes with savings passed on to you.

- Our steel-cast bronze wears much longer and is far tougher and stronger than the best sand cast product. Being absolutely free of any hidden sand particles insures a longer life for your shaft.

- Because all your machining can be done by us internally, you are saved additional machine time in your own plant, resulting in lower costs. All castings are machined, no bronze is shipped in an “as cast” state.

- Our crystal control method of casting allows for a uniform or “isotropic” crystal structure, unlike that found in sand cast metals, while raising physical characteristics far above the requirements for similar formula sand castings.

Order with confidence, Save time, money.

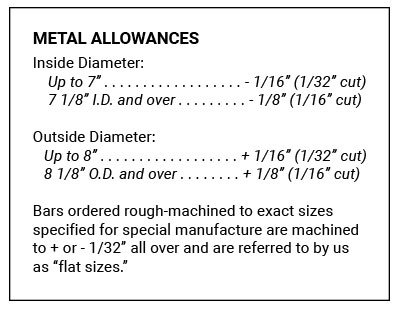

Magnolia semi-finished bronze bushings and bearings, cast in steel molds, are available in sizes and combinations ranging from 12″ (continuous cast up to 12″) to 34″ O.D. By ordering Magnolia semi-finished machined bronze to your size, you will save 15 to 35% of purchase weight over rough cast. Requiring only a finish cut to clean, you cut machine time in half and eliminate 100% of your rejects.

Magnolia’s semi-finished or rough machined (flat size) parts are guaranteed to machine in your shop to your exact finished sizes. Magnolia rough machine sizes already include an 1/8″ overage on each dimension, above the finished size. When ordering Magnolia semi-finished parts, using your finished dimensions, you are assured enough material to clean to your requested size.

The Magnolia Advantage

Laboratory Tests Prove it!

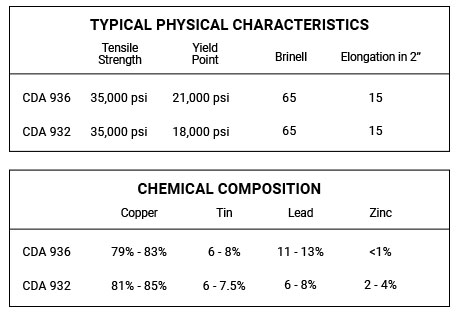

Tests conducted by a national laboratory verify that Magnolia CDA 936 consistently out performs CDA 932 (SAE 660) under the most difficult conditions in test after test. The bearings were run with inadequate lubrication until temperatures exceeded 400ºF. Under these severe conditions, in some instances teh CDA 932 wore out three times faster than CDA 936. In no test did CDA 932 out perform CDA 936.

Newly completed tests by a major university also prove that Magnolia’s CDA 936 alloy has a significantly higher failure resistance than CDA 932. Despite extreme circumstances, operating without lubrication, CDA 936 ran an average of 78% longer than CDA 932, and with none of the incidents of severe shaft scoring found among the CDA 932 tests.

CDA 936 because:

- Higher lead content gives better lubricating properties and provides better co-efficient of friction. Bearings run cooler, last longer.

- One and a half times as resistant to pounding.

- Acid resisting to sulphite fluids due to lower zinc. CDA 936 can be used in areas where CDA 932 would corrode.

Bushings for: Presses – mining equipment – mixers – crushers – refiners – rubber mills – compressors

Whatever your bronze needs, Magonila stands ready to respond. Maintaining a large inventory and wide range of sizes in stock enables Magnolia to act immediately in a critical delivery situation.

With the elimination of patterns, core boxes and costly rejects, your savings on replacement parts are considerable. Combine that with Magnolia’s computerized costing system, upgraded machining equipment and our own foundry, and see why we provide among the most competitive prices in the industry.

Magnolia also makes:

- Continuous Cast Bronze up to 12 1/2″ O.D. Lengths up to 144″

- Completely finished bronze parts from 1″ to 34″ O.D.

- Lead and tin base babbits

Special Alloys:

Magnolia also casts and carries CDA 937 (Cert 64). #120 High Lead Bronze (20% lead) similar to an SAE 67 Alloy, AA Hard or CDA 9093 and SAE 63. In addition to these standard alloys, Magnolia is capable of casting most tin bronzes and leaded tin bronzes on a special order basis. We will be glad to quote promptly.

Magnolia Guarantees No Rejects

Magnolia Bronzes are guaranteed to be free from all defects. In Magnolia Bronze there are no blow-holes, no sand spots, no segregated elements, no flaws… no under-surface faults of any kind to cause rejection.

In accordance with industry practice, guarantee is limited to free placement of material returned. But why just “hope” to get a good casting? Magnolia’s quality control procedure has resulted in returns of less than 1/2 of 1% of all bronze shipped over the last 10 years. This standard of excellence combined with our special alloy and our unique casting process assures you of the best possible value in bearing bronze.